|

| September 02, 2014 | Volume 10 Issue 33 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

Micro fasteners introduce big solutions for consumer electronics

By Jay McKenna, PennEngineering

Sub-compact consumer electronic devices can present particularly outsized challenges when it comes to hardware for attaching components and assemblies. Designers must wrestle with restrictive design envelopes, limited footprints for fastener placement and installation, and potentially high parts counts. As solutions, extremely small "micro" fasteners have made significant headway in the global marketplace coinciding with the ongoing evolution of smaller, lighter, and thinner sub-compact consumer electronic products ranging from cell phones to tablets and all innovations in between.

Among the early micro-fastener types to gain a foothold, threaded "micro" screws were developed in a variety of materials, head styles, and driver types. While they remain viable options in many applications, their requirements for additional mating hardware and locking patches will run counter to the goal of keeping the amount of hardware -- and end-product weight -- to a minimum.

As it turns out, threaded micro screws marked only the beginning of a new dawn in micro-fastener technology.

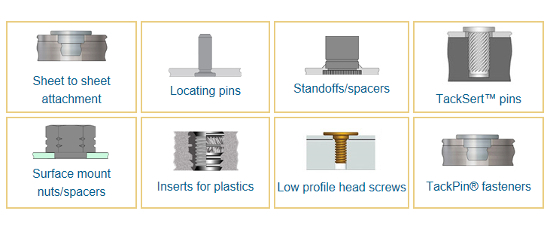

Among notable examples, self-clinching micro fasteners (some threaded and some not) have been introduced over the years (and the portfolio is still expanding) to offer more choices for attaching aluminum and other thin ductile metals. Turning to plastics, metal inserts have arrived to enable reliable and secure attachment in plastic materials ranging from ABS to polycarbonate.

All these micro fasteners become permanent and integral parts of a component or assembly; no secondary operations are necessary; they will not loosen or fall out; and they never have to be handled again (if at all, in cases of automated installation).

In the "micro" world, designers should understand that these relatively smaller fasteners are not simply scaled-down versions of their larger counterparts. When fastener types are downsized to lengths as short as 2 mm, thread sizes as small as M1, and diameters of 1 mm, issues relating to tight tolerances and performance values, among others, become magnified. Unique features engineered into the fastener often become both critical and essential, and specialty design and engineering come into play.

Popular micro-fastener types from PennEngineering

Self-clinching microPEM TackPin fasteners in phone application.

Following is a brief profile of some of the more popular micro-fastener types making their marks as especially good fits for sub-compact electronic assemblies:

- Threaded self-clinching micro standoffs and spacers for spacing or stacking internal components in extremely limited space applications. Standard types have been developed with threads as small as M1 / #0-80 and in lengths as short as 2 mm / .080 in.

- Unthreaded self-clinching micro-locating pins for locating, positioning, and/or alignment applications. Standard versions are manufactured from age-hardened A286 stainless steel and designed with diameters as small as 1 mm / .040 in. and in lengths as short as 2 mm/.080 in.

- Threaded surface-mount micro spacers for nut and spacer applications involving printed circuit boards. They install permanently (in the same way and at the same time as other board components) and can be specified in thread sizes as small as M1 / #0-80 and lengths as short as 1 mm / 0.62 in. Ultimately, these spacers eliminate any need to place hardware manually on a populated printed circuit board.

- Thru-threaded brass micro inserts for plastics in thread sizes as small as M1 and in a variety of lengths. They will install (with ultrasonic equipment or with a thermal press) either in straight or tapered mounting holes, and their symmetrical design adds value in time savings during production by eliminating any need for orienting the fastener prior to installation.

- Unthreaded stainless or aluminum micro pins (PEM TackSert) for attaching top panels of any material (as thin as 0.2 mm / .008 in.) securely to a base panel or chassis manufactured from common magnesium die-cast materials (such as AZ91D) or plastics (such as ABS). Unlike conventional micro screws, the pins eliminate much of the handling issues and reduce the total installed cost. From a design perspective, their unique diagonal knurl effectively holds the top panel to a base panel or chassis by broaching into the base panel/chassis using a simple press-in action without requiring heat or ultrasonics.

You can learn more about the specifics of these micro fasteners by clicking here.

Going forward, innovations in micro-fastening technology will certainly advance, in part, as a response to customer challenges and needs. A promising trend has been a steadily growing partnership between OEM designer and fastener manufacturer to develop the most practical solution for an application. Knowledge that a hardware design team is equipped to deliver, based on experience, ultimately can make all the difference as consumer electronics and similar products turn even smaller, thinner, and lighter.

Jay McKenna is Global Business Manager-microPEM Fasteners at PennEngineering, 5190 Old Easton Road, Danboro, PA 18916-1000 USA. Tel: +1-215-766-8853. Email: jmckenna@pemnet.com. Website: www.pemnet.com

Published September 2014

Rate this article

View our terms of use and privacy policy